Seamless alloy steel tubing is an essential component in many industries that require strong and durable materials. It is widely used in various applications that require high strength and resistance to corrosion. In this blog post, we will discuss the significance of seamless alloy steel tubing, focusing on ASTM A519 grade 4140, 4130, 4140, and 42CrMo.

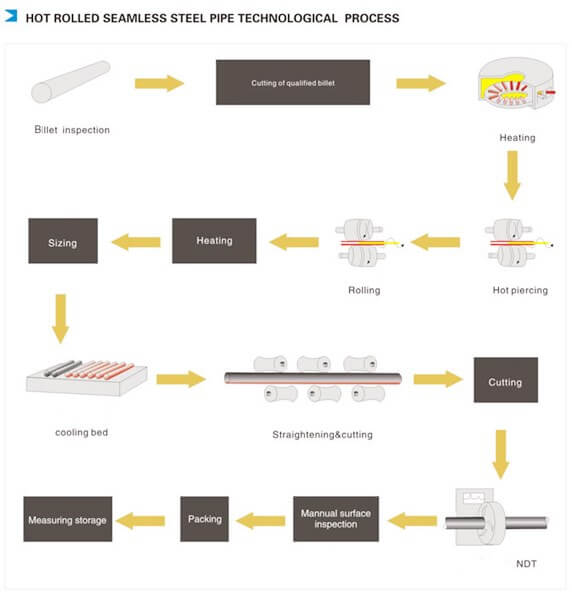

Seamless alloy steel tubing is made by extruding a steel billet through a piercing hole in a seamless tube round. This manufacturing process eliminates the need for welding, which can create weak spots and reduce the overall strength of the tubing. The seamless construction ensures that the material has a uniform structure, which guarantees its mechanical properties and makes it suitable for critical applications.

One of the key benefits of seamless alloy steel tubing is its high strength. ASTM A519 grade 4140, 4130, 4140, and 42CrMo are known for their exceptional tensile and yield strengths, making them suitable for applications that require reliable and robust materials. These grades of steel tubing can withstand high-pressure environments and heavy loads, making them ideal for industries such as oil and gas, automotive, and aerospace.

The oil and gas industry heavily relies on seamless alloy steel tubing for its operations. This industry requires materials that can withstand extreme conditions, such as high temperatures and corrosive environments. Seamless alloy steel tubing, with its superior strength and resistance to oxidation, ensures the safe and efficient transportation of oil and gas from wells to refineries.

Similarly, the automotive industry relies on seamless alloy steel tubing for a multitude of applications. From suspension components to driveshafts, this type of tubing offers the required strength and rigidity to withstand the demands of high-performance vehicles. Seamless alloy steel tubing is also used in the manufacturing of engine components, such as exhaust headers and intake manifolds, which require materials that can handle high temperatures and corrosive gases.

Moreover, the aerospace industry also benefits from seamless alloy steel tubing. This industry has stringent requirements for materials, as they must be able to withstand the extreme conditions of space travel. Seamless alloy steel tubing, with its high strength, lightweight construction, and resistance to fatigue, meets the stringent demands of the aerospace industry.

Seamless alloy steel tubing is also essential in various construction applications. It is commonly used in the construction of bridges, buildings, and infrastructure due to its high strength and durability. Additionally, seamless alloy steel tubing finds application in the manufacturing of machinery and equipment, providing the necessary structural support and longevity.

In conclusion, seamless alloy steel tubing, specifically ASTM A519 grade 4140, 4130, 4140, and 42CrMo, plays a crucial role in various industries. Its high strength, resistance to corrosion, and ability to withstand extreme conditions make it an ideal choice for critical applications. Whether it is in the oil and gas industry, automotive sector, aerospace field, or construction realm, seamless alloy steel tubing ensures the safety, reliability, and efficiency of diverse processes.