Product Introduction

PSL1, PSL2 and Acidic Media Types. Usually PSL1 is used, which is equivalent to ASTM A106 B and A53 B. PSL2 is a higher specification grade pipe with stricter requirements for chemical and mechanical strength. PSL2 requires more test methods such as non-destructive testing, CVN impact testing, DWT, etc. API 5L B PSL2 is represented by API 5L BN/Q/R/M. Acidic medium: For acid pipelines such as H2S environment, the pipeline material has typical requirements for chemical elements such as carbon, phosphorus and sulfur. Reference standard NACE MR0175.Suffix Letter

Product Type

Seamless Type: including hot-rolled seamless pipes over 3 inches, cold-rolled seamless pipes under 3 inches. ERW Welding Type: Resistance Welding, suitable for pipes up to 24 inches. Straight Seam Submerged Arc Welding Type: Longitudinal segmented arc welding, suitable for pipes with an outer diameter of 20 inches to 48 inches. LSAW is also known as JCOE, which means making shapes from J-shaped, C-shaped, O-shaped, and then cold-expanded pipes. SSAW/HSAW Type: Spiral Submerged Arc Welding or Spiral Saw for pipe up to 100" OD. API 5L Grade B, ASTM A106 Grade B and A53 Grade B, these three materials are the most commonly used materials in pipeline construction or oil and gas and liquid transportation industries. ASTM 106 Pipe refers to hot-rolled or cold-drawn (rolled) seamless carbon steel pipe. ASTM A53 pipe includes welded and seamless steel pipes of carbon black material, and in some cases hot-dip galvanized (galvanized).Our Service

Grade: API 5L Grade BN/Q/M/NS/QS/MS. Manufacturing Type: Seamless and welded ERW, LSAW, SSAW/HSAW. Outer Diameters for Seamless: 1/2” – 24”. OD for ERW: up to 24”. OD for LSAW: 16” to 48”. OD for SSAW/HSAW: up to 100”. Range of Thickness: Sch 20, SCH 40, SCH STD, SCH 80, SCH XS, SCH 120, SCH XXS, SCH 160. Range of Length: SRL, DRL, 20FT, 40FT. Product Specification Level: PSL1, PSL2, Sour Services. Ends: Plain, Beveled, Threaded. Coating Available: FBE, 3PE/3LPE, Black Painting, Varnished, Anti-rust oil, Galvanized, CRA, CWC.API 5L Grade B Pipe PSL1 Chemical Composition

API 5L Grade B Pipe PSL1 Mechanical Properties

API 5L Grade B Pipe PSL2 Chemical Composition

API 5L Grade B Pipe PSL2 Mechanical Properties

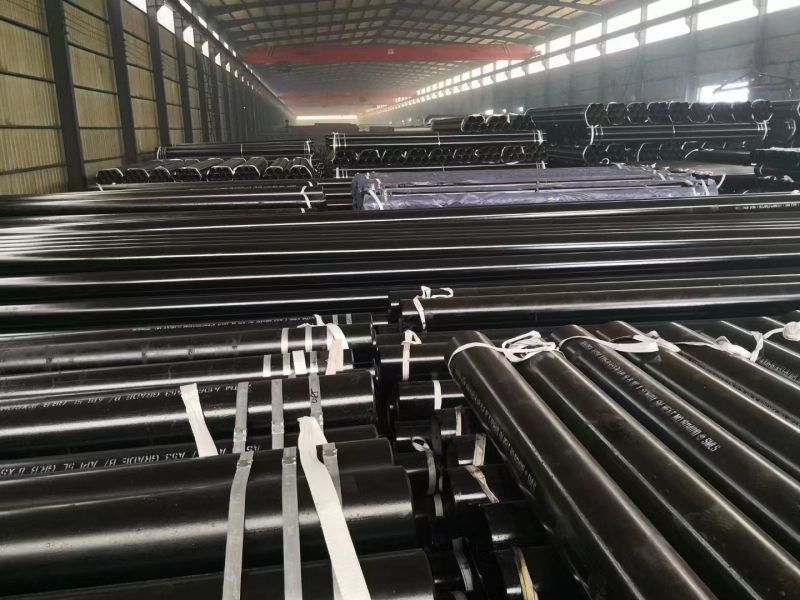

Product Display

Suffix letters specify pipeline delivery conditions: R: When rolling. N: normalizing rolling, normalizing forming, normalizing. Q: Tempering and Quenching. M: Thermomechanical rolling or thermomechanical forming. S: Sour medium with PSL2 tubing for NS, QS, MS, e.g. API 5L Grade B NS, API 5L B QS. Seamless and welded (ERW, LSAW, SSAW/HSAW) types.