Pipe Specifications

Standard: ASTM A519 / ASME SA 519 Size: 16mm-89mm Schedule: 10-XXS / Thk Shape: Round or Special sections. Length: Single random length/ Double random length or as customer’s actural request Grade: SAE 1010 Condition: The purchaser shall specify a sizing method and, if required, a thermal treatment. Sizing Methods: ASTM A519 Grade 1010 Hot-Finished Mechanical Tubing 2. ASTM A519 Grade 1010 Cold-Worked Mechanical Tubing 3. ASTM A519 Grade 1010 Rough -Turned Mechanical Tubing 4. ASTM A519 Grade 1010 Ground Mechanical Tubing HF-Hot Finished, CW-Cold worked, RT-Rough Turned, G– Ground. Thermal Treatments: A-Annealed, N– Normalized, QT-Quenched and Tempered, SR-Stress Relieved or Finish Anneal

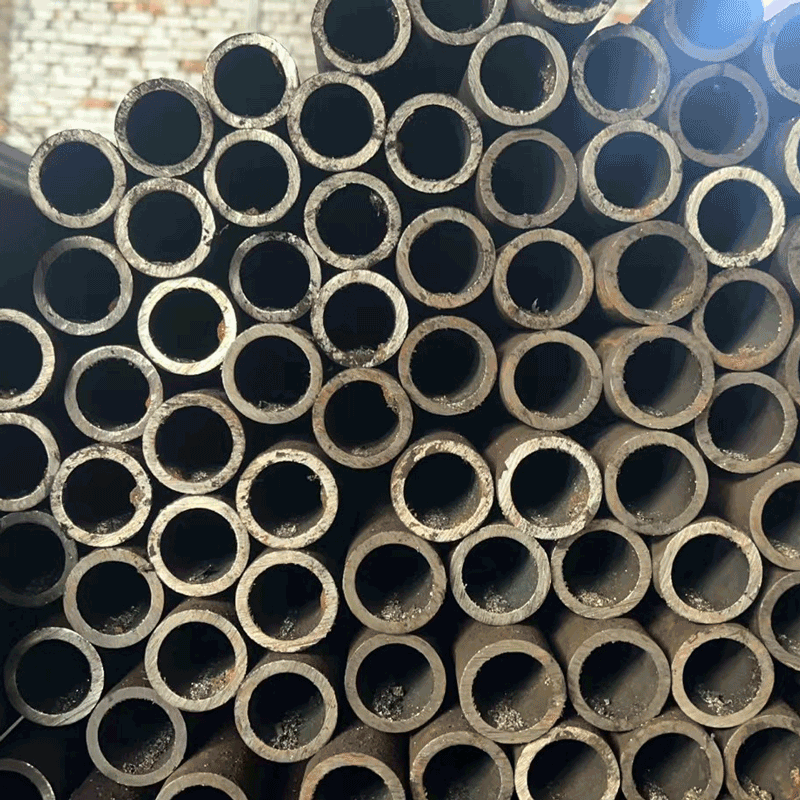

Product Display

ASTM A519 SAE1010 Seamless Steel Pipe Chemical Composition (%)

| Grade | C | Mn | P<= | S<= |

| 1010 | 0.08-0.13 | 0.30-0.60 | 0.040 | 0.050 |

Wall Thickness Tolerances for Cold Drawn Seamless Steel Pipe:

| Wall Thickness Tolerances for Cold Finished Tubing | ||

| Wall Thickness S/ Outside Diameter D (%) | Wall Thickness Tolerance (±%) | |

| Inside Diameter D < 38.1mm | Inside Diameter >= 38.1 | |

| <=25% | 10.0 | 7.5 |

| > 25% | 12.5 | 10.0 |